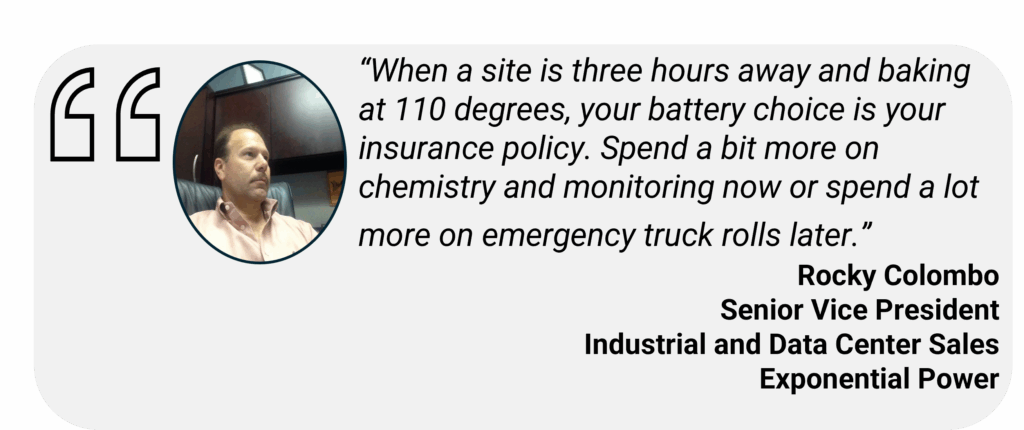

Edge data centers are sprouting up everywhere: on rooftops, cell towers, and compact enclosures far from climate-controlled facilities. When temperatures soar to 110°F, cooling systems max out and batteries face their biggest test. Battery failure means site failure.

The urgency behind this challenge

Record-breaking heat waves are coinciding with explosive growth in remote edge deployments and stricter uptime requirements. While ASHRAE guidelines recommend IT equipment operate between 64-80°F, many edge sites regularly exceed 110°F, pushing both hardware and backup power systems well beyond their comfort zones.

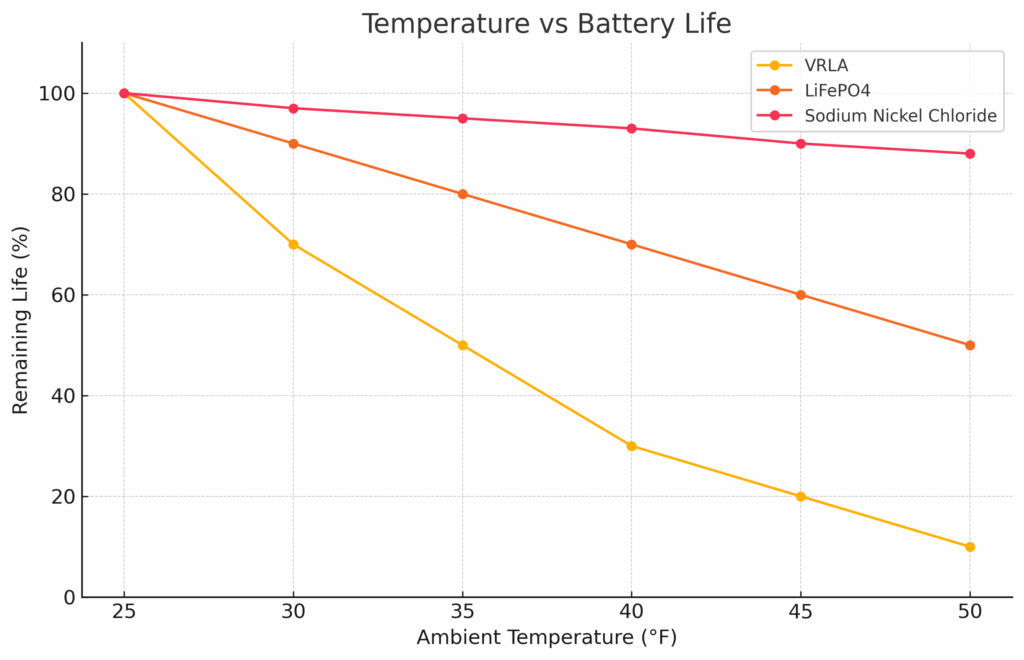

Which chemistries actually tolerate heat?

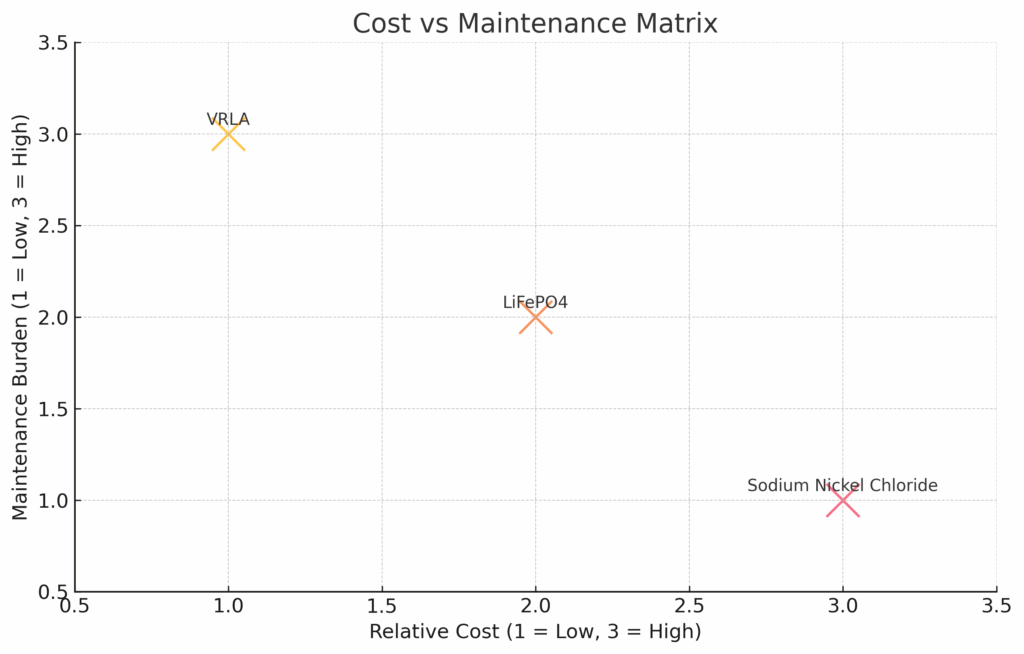

VRLA Lead-Acid (AGM/Gel) Batteries

Lower upfront costs come with higher operational overhead in hot environments. The industry standard warns that every 15-18°F above 77°F can slash VRLA battery lifespan by roughly 50%. Operating continuously at 95°F means you’ll likely see only half the rated service life. IEEE 1188 standards require regular performance testing, and elevated temperatures force more frequent and costly maintenance cycles.

Lithium Iron Phosphate (LiFePO₄) Batteries

LFP technology maintains stable capacity under heat stress and delivers significantly more charge cycles than VRLA, making the total cost of ownership attractive despite higher initial investment. While these batteries tolerate extreme temperatures better, prolonged exposure above 113°F still accelerates degradation, making proper ventilation and thermal monitoring essential, not optional.

Sodium Nickel Chloride (SMC / NaNiCl₂) Batteries

These “molten salt” systems operate at elevated internal temperatures by design and handle ambient conditions from -40°F to 140°F without breaking stride. Their sealed, non-venting construction eliminates fire risks and reduces both maintenance visits and cooling demands. The barriers are higher acquisition costs and limited supplier availability.

Practical ways to stretch battery life in hot boxes

- Position batteries away from sun-exposed walls and rooftops. Even small temperature reductions extend service life significantly. Design clear exhaust pathways or passive ventilation to prevent heat buildup inside enclosures from accelerating cell degradation.

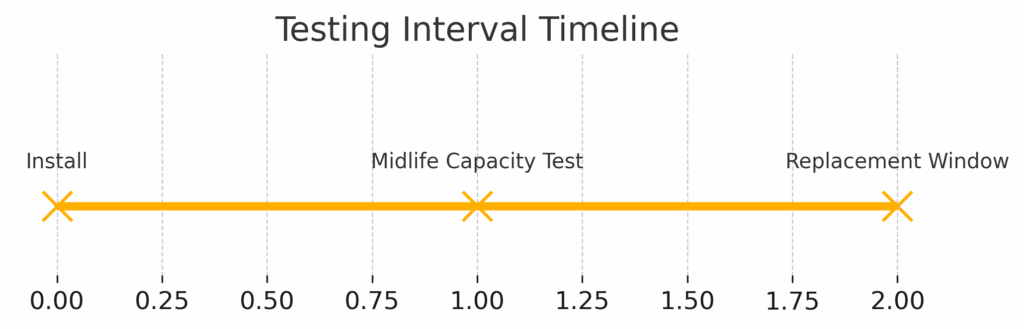

2. Install temperature monitoring with alert thresholds set at 86-95°F for VRLA systems and 104-113°F for LFP batteries. Adhere to IEEE 1188 testing schedules: perform capacity tests within 25% of expected lifespan or every two years, whichever occurs first

3. Enable temperature compensation on lead-acid charging systems to minimize thermal stress. Plan for mid-life capacity assessments or proactive replacements. Ignoring heat effects destroys your total cost calculations and uptime guarantees.

Key takeaways

110 °F is well above ASHRAE’s recommended window, so heat impact on backup power is real.

VRLA is cheapest upfront, then loses life fast above 25 °C and needs frequent testing.

VRLA is cheapest upfront, then loses life fast above 25 °C and needs frequent testing.

![]() LiFePO₄ rides heat better and slashes maintenance, yet keep it under about 45 °C for best life.

LiFePO₄ rides heat better and slashes maintenance, yet keep it under about 45 °C for best life.

Sodium nickel chloride thrives in extreme ambient temps and is nearly maintenance free; cost and availability can be hurdles.

Sodium nickel chloride thrives in extreme ambient temps and is nearly maintenance free; cost and availability can be hurdles.

Monitoring, temperature alarms, and IEEE-driven testing schedules protect uptime and budgets

Monitoring, temperature alarms, and IEEE-driven testing schedules protect uptime and budgets

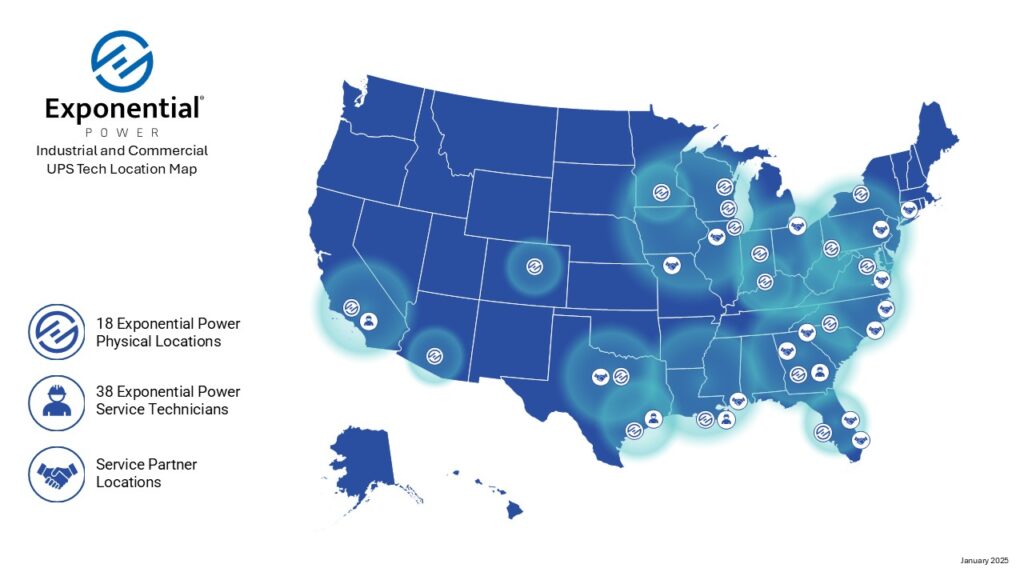

Ready to talk specifics?

Exponential Power brings nationwide 24/7 service, IEEE and NERC compliance work, and real monitoring expertise to keep edge data centers online. If you are staring at a map of hot, unmanned sites and wondering which path keeps total cost of ownership in check, let’s talk. Our engineers will model heat impact, compare lifecycle costs across chemistries, and spec monitoring that pays for itself. Contact us for a consult or request a proposal.