Why there is confusion in the market about lithium-ion charging

Many fleets adopted lithium before their facilities had the power and chargers to support it, which leads to an install-day surprise: modern lithium battery chargers may not run on the outlets that fed yesterday’s lead-acid battery chargers. Projects stall, timelines slip, and operators lose shifts.

Why it matters now

Electric lift trucks are taking share and some fleets are standardizing on lithium batteries to cut maintenance and boost uptime. Market research points to strong growth for electric forklifts through 2030, which pushes charging rooms and panels to their limits.

What is really causing the gap

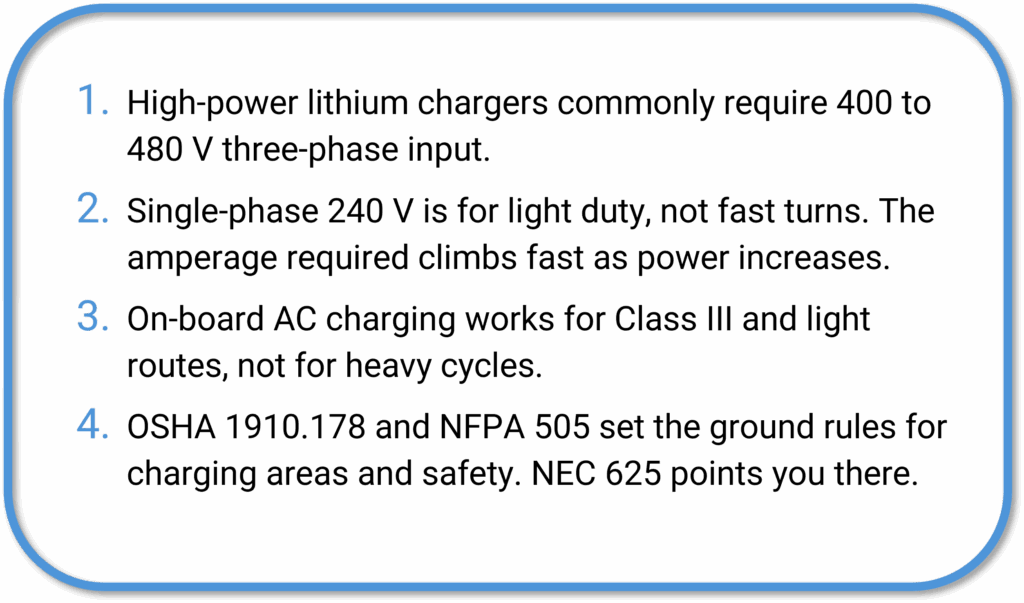

Higher charger power, different input. High-power lithium chargers are typically three-phase, often 480 V, to support opportunity and fast charging.

Single-phase cannot carry big loads. Across the market, 240 V single-phase charging comes up a lot. The constraint is simple math. A 15 to 20 kilowatt charger pulls about 62 to 83 amps at 240 V single-phase before losses. That load stresses panels and wiring, creates heat, and limits hardware options. For anything beyond light duty or small packs, most vendors specify three-phase.

Light-duty exceptions exist. Class III pallet jacks and walkies often use on-board AC charging at 120 or 240 V for charging. Several pallet jack platforms ship with an integrated 120 VAC charger, which is fine for small packs and lower daily throughput.

Codes and safety add complexity. Charging areas for powered industrial trucks must be designated and equipped per OSHA 1910.178, with ventilation and protection of apparatus. Fire safety for industrial trucks is governed by NFPA 505. NEC Article 625, which covers EV charging, includes an informational note that points industrial trucks back to NFPA 505, a common source of confusion for facilities teams.

How to upgrade without blowing the capital budget

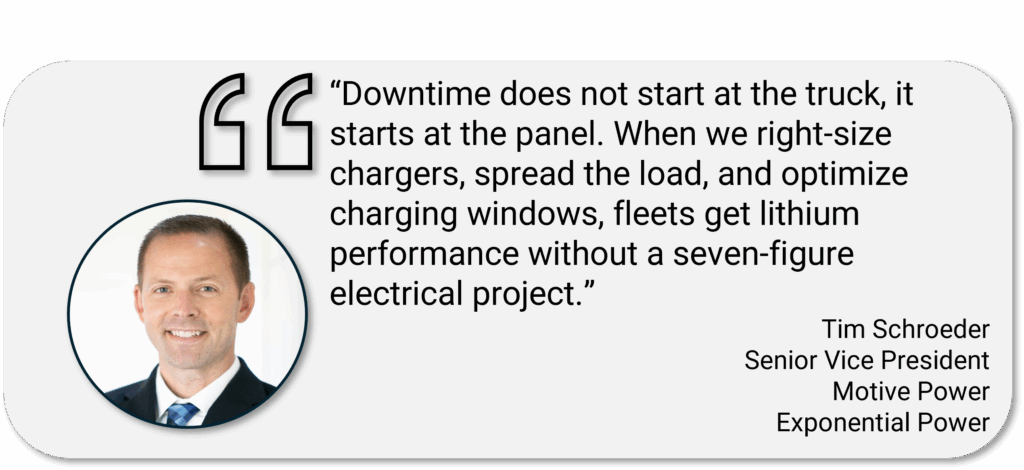

1) Start with a load study and a phasing plan. Map every truck, charger, and shift. Model coincident demand, not nameplate totals. Stagger charge windows and zones to flatten peaks. Many fleets avoid a service upgrade with scheduling alone.

2) Right-size chargers to routes. Put your highest power, three-phase chargers where your highest throughput trucks touch down. For lighter routes, deploy lower power chargers or on-board AC where the duty cycle allows. This mix keeps uptime high without oversizing every port.

3) Add step-up only where you need it. If your building has 208 or 240 V three-phase but not 480 V, feed a small cluster of fast chargers with a dedicated step-up transformer. This targets spend where it moves the needle instead of upgrading a whole service. Field forums and charger specs reflect many forklift rooms fed at 480 V three-phase for higher outputs.

4) Design charging zones, not a single room. Place chargers near docks and pick aisles to enable true opportunity charging. That lowers queuing at shift change and reduces both the number and size of high-power chargers you need.

5) Do not skip compliance. Align layouts with OSHA 1910.178 and NFPA 505 from day one. You protect people, avoid rework, and keep insurance audits simple.

What failure looks like, and the benefit of getting it right

When chargers are under-powered or mis-matched, trucks die mid-shift. Picks slip. Crews go to overtime. When infrastructure is sized and scheduled correctly, fleets see shorter turnarounds, and cleaner shift starts. Operators stop firefighting, supervisors get their hours back, and fleet management gets predictable costs with motive power that supports uptime.

When chargers are under-powered or mis-matched, trucks die mid-shift. Picks slip. Crews go to overtime. When infrastructure is sized and scheduled correctly, fleets see shorter turnarounds, and cleaner shift starts. Operators stop firefighting, supervisors get their hours back, and fleet management gets predictable costs with motive power that supports uptime.

Where Exponential Power helps

We support two brands, Exponential Power and Greencubes. Our focus is designing, supplying, and servicing motive power systems for warehouse and manufacturing fleets. We size chargers, balance loads, and lay out charging zones tailored to your shift patterns.

We support two brands, Exponential Power and Greencubes. Our focus is designing, supplying, and servicing motive power systems for warehouse and manufacturing fleets. We size chargers, balance loads, and lay out charging zones tailored to your shift patterns.

Whether your fleet runs on lithium, lead-acid, or a mix of both, you get a single partner for batteries, chargers, and power distribution. Services include site assessments, power studies, installation, and commissioning. We add monitoring that tracks charge events, temperature, and state of charge, then use that data to optimize charge intervals and extend battery life.

With field coverage, and stocked parts, we keep trucks on the floor and cut rentals. We also train operators and maintenance staff on safe charging practices aligned with OSHA 1910.178 and NFPA 505. If you run multiple sites, we standardize charger models and settings to simplify fleet management across locations.

Quick recap

Ready to close your gap

If you are sorting out forklift batteries, chargers, and facility power, bring in Exponential Power. Our team will audit your site, right-size chargers to routes, design safe charging zones, and phase the build so it fits your capital plan. Get a consultation or request a proposal and put your motive power upgrades on a predictable path.